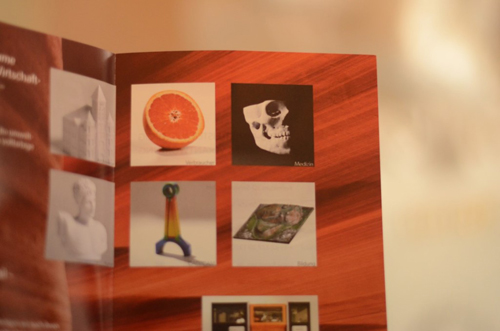

3D printing is the buzzword of the moment. Although the first 3D printer was already invented in the 1980ies, the technology has only recently become accessible to a larger audience. There are many models of 3D printers working with different materials, among them paper. We met Gunther Bigl, the owner of FORMICUM and the first full-colour paper 3D printer in Germany. He showed us how his printer works as well as some of the amazing 3D prints he produces.

How did you get into contact with 3D printing?

I am a biologist and was working in research and development for animal husbandry. I wanted to develop a 3D scanner which makes it possible to scan living animals, which move around. That’s how I came into contact with 3D printing. I became fascinated with the Mcor printers, who use normal paper as base material, as they are very environmental friendly – opposed to other 3D printing methods. 3D printing with paper is quiet, nontoxic and save. The paper, the water soluble glue, the ink as well as the whole printed model can be recycled as wastepaper.

How does 3D printing with paper work?

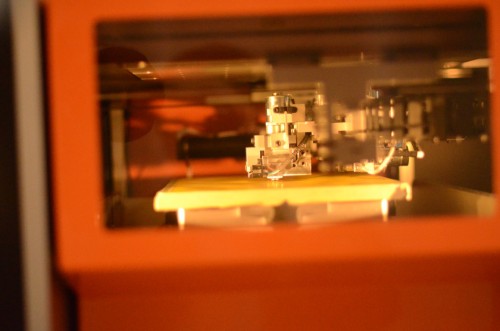

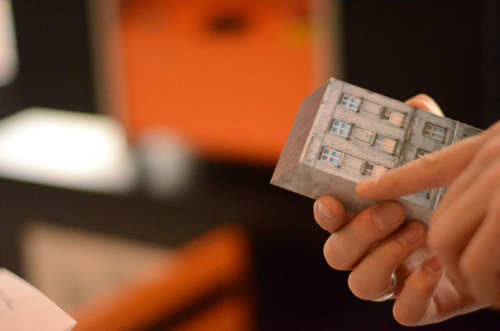

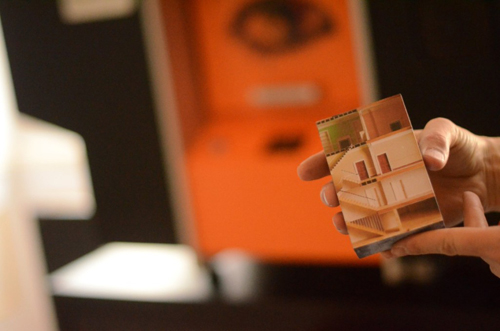

There are two steps. First we print the contour of each layer of the object on a normal EPSON printer. We need ca. 100 sheets of 80g paper for one cm of the object. The second step is the actual 3D printing. The technique applied is called Selective Deposition Lamination (SDL). Successive layers of paper are laid down and glued together. The adhesive is applied selectively with a much higher density of adhesive in the area that will become the object, and a much lower density of adhesive in the surrounding area that will serve as the support. Each new layer is fixed with the help of pressure. A blade cuts one sheet of paper at a time, tracing the object outline to create the edges of the object. The sequence is: sheet of paper – glue – pressure – cutting – next sheet of paper until the object is printed. When it is ready you take out the whole paper block and manually remove the support material.

Who are your customers?

They work in diverse fields such as medicine, architecture, arts, entertainment, industrial prototyping, education etc. Our 3D models are, for instance, used in the restoration of art objects. Imagine one half of a sculpture is missing. With the help of digital mirroring we can reconstruct the sculpture and 3D print it. Another example, archeological museums like to make CT scans of their mummies. We can extract the content of the mummies from these CT scans and print it. The same is true for CT scans of living human beings. We can print a bone based on CT scans and the surgeon can simulate the surgery based on our 3D model of the bone. With each new client we meet comes a new idea – the possibilities are infinite.

Which was the most original object you 3D printed?

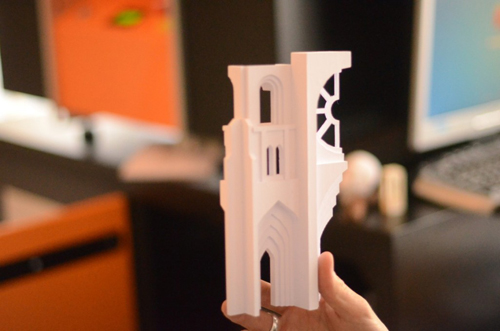

This rhinoceros or a gothic cathedral – two quite intricate models perfectly showing the possibilities of our machine. Currently we are working on 3D printing a monument in Leipzig, it will be made of different parts.

Thank you so much Gunther Bigl

for taking the time to answer our questions!

Photo credits: Design & Paper, Outline Pictures (cover photo)